-

FDML 750x710 .40

fire damperExcl. Tax: €1,230 Incl. Tax: €1,488in 1-2 weeksPipe: 750x710 -

FDML 750x710 .40 A

fire damperExcl. Tax: €1,176 Incl. Tax: €1,423in 1-2 weeksPipe: 750x710 -

FDML 750x710 .40 B

fire damperExcl. Tax: €1,225 Incl. Tax: €1,482in 1-2 weeksPipe: 750x710 -

FDML 750x710 .41

fire damperExcl. Tax: €1,591 Incl. Tax: €1,925in 1-2 weeksPipe: 750x710 -

FDML 750x710 .41 A

fire damperExcl. Tax: €1,540 Incl. Tax: €1,864in 1-2 weeksPipe: 750x710 -

FDML 750x710 .41 B

fire damperExcl. Tax: €1,590 Incl. Tax: €1,923in 1-2 weeksPipe: 750x710 -

FDML 750x710 .50

fire damperExcl. Tax: €1,182 Incl. Tax: €1,431in 1-2 weeksPipe: 750x710 -

FDML 750x710 .50 A

fire damperExcl. Tax: €1,131 Incl. Tax: €1,369in 1-2 weeksPipe: 750x710 -

FDML 750x710 .50 B

fire damperExcl. Tax: €1,180 Incl. Tax: €1,428in 1-2 weeksPipe: 750x710 -

FDML 750x710 .51

fire damperExcl. Tax: €1,479 Incl. Tax: €1,789in 1-2 weeksPipe: 750x710 -

FDML 750x710 .51 A

fire damperExcl. Tax: €1,413 Incl. Tax: €1,710in 1-2 weeksPipe: 750x710 -

FDML 750x710 .51 B

fire damperExcl. Tax: €1,462 Incl. Tax: €1,769in 1-2 weeksPipe: 750x710

F-C2

The F-C2 cartridge fire dampers are fire dampers for circular air ducts with fire resistance classes EI60S, EI90S and EI120S. The F-C2 fire dampers are a passive fire protection element designed to separate individual fire compartments and prevent the spread of gases, smoke and flame. The F-C2 fire dampers are equipped as standard with a thermal fuse (H0) that closes the damper when the temperature reaches 72°C or can be equipped with a limit switch (H1) that signals the damper position status.

The F-C2 fire damper consists of galvanized steel sheet, steel (up to size 125) or calcium silicate blade (from size 140), graphite fire laminate and polyurethane foam. The damper is also fitted with an intumescent seal which increases its volume in the event of a fire. The maximum permissible pressure on the damper is 300 Pa.

CFDM

The fire dampers CDFM are closures in ducts of HVAC equipment, which prevent the spread of fire and combustion products from one fire compartment to another by closing the air ducts in the places of installation according to ČSN 73 0872.

The damper blade automatically cuts off the air passage by means of a closing spring. The closing spring is activated by initializing the thermal fuse. The spring closes the damper blades.

After closing the blade, the damper is sealed against the passage of smoke by means of a foam seal. At the same time, the damper blade is embedded in a mass, which increases its volume due to the increasing temperature and closes the air duct airtight.

The fire damper can be equipped with a disc valve in both combinations - for outlet (TVOM) and for inlet (TVPM). The valve is fixed by springs in the damper body and can be easily disconnected from the damper. The valve can only be installed on a damper with an extended body (CFDM-V).

Characteristics of dampers:

- CE certification according to EN 15650

- tested according to EN 1366-2

- classified according to EN 13501-3+A1

- fire resistance EIS 120, EIS 90, EIS 60

- tightness according to EN 1751, class 2 through the damper blade, external tightness is equal to the duct system

- corrosion resistance according to EN 15650

- EC Certificate of Conformity No. 1391-CPR-2018/0129

- declaration of performance No. PM/CFDM/01/20/1, PM/CFDM-V/01/20/1

- hygienic assessment - Opinion No. 1.6/pos/19/19b

SC / SCV

The SC+ fire dampers are fire shutters designed for installation directly in circular ducts. The SCV+ are fire dampers with disc valve designed for circular ducts suitable for air supply and exhaust. Exceptions in this category are dampers marked SC0 or SCV0, which are designed only for extraction and are certified only for integrity “E”.

The fire dampers have a thermal fuse which melts when the temperature exceeds 72 °C and closes the damper. The *fire resistance* of the damper is EI60S/90/120, depending on the design, wall construction and installation method. The fuse is replaceable and can be ordered separately.

BX-1H

The BX-1H circular fire disc valves are designed for installation in vertical fire partitions or at the beginning of ducting routes. The regulating disc allows the air flow regulation and the locking is provided by a lock nut. In case of a fire, when the temperature exceeds 72 °C, the BX-1H valve closes and separates adjacent fire compartments.

The BX-1H fire valve is classified according to ČSN EN 13501-3+A1:2010 as El 60 S. The design of the valve complies with ČSN EN 15650:2010. A 35 mm long sleeve (mounting ring) is standardly included (67, 120 or 150 mm long sleeves are available on request).

KSO-F

The fire damper valve KSO-F is made from galvanized steel sheet equipped with white color RAL 9010. Fire damper valve has seailing from foam product, regulation disc allows easily air flow regulation and fix of position via contra nut. The valve is supplied with mounting ring KKT also made of galvanized sheet steel. Suitable for horizontal ventilation pipeline. KSO-F is intended for use as a fire closure of ventilation systems.

Resistance of this ventilation device KSO-F was tested according to EN 13501-3 authorized testing and fire resistance classification cap fitted in the wall construction is E120.

F-B90

The F-B90 multiblade fire damper is designed to divide fire compartments and prevent the spread of toxic gases, smoke and flames. The F-B90 fire damper is an element of passive fire protection. The F-B90 fire damper is classified and certified with EIS criteria according to EN 1366-2. The fire resistance rating depends on the type of damper and the installation method.

The F-B90 multiblade fire damper with grilles on both sides is designed for fixed installation in the fire partitioning structure without air duct connection. The F-B90 multiblade fire damper without grilles is designed for installation in ducts.

The F-B90 fire damper is available with manual operation or with actuator.

Catalogue of the product series: F-B90-en.pdf. Declaration of performance of the product series: F-B90_declaration-of-performance.pdf.

F-B90 fire damper with manual operation

The trigger mechanism of the F-B90 fire damper is activated when the ambient air temperature reaches 74 °C. In the event of a fire, the damper closes automatically within 10 seconds after the thermal fuse has melted. Once the damper is closed, the blades remain locked in the closed position and can only be opened manually. On request, the fire dampers can be supplied with limit switches to signal the position of the blades.

F-B90 fire damper with actuator

The F-B90 fire damper with actuator closes on a signal from the building management system (BMS) or when the temperature exceeds the thermoelectric temperature sensor, which is standard on every damper. If the temperature exceeds 72°C, the actuator power circuit is interrupted and the spring closes the damper blades within 20 seconds.

F-B90 damper types

• 00

Damper without protective grilles designed for installation in ducts.

• 01 or 02

Damper fitted with a protective grille on one side, version 01 (grille in galvanised steel sheet) or 02 (grille in white powder coated RAL 9003). The grille can be fitted on either side of the damper.

• 11 or 22Damper fitted with protective grille on both sides, version 11 (grille in galvanised steel sheet) or 22 (grille in white powder coated RAL 9003). Serves as a wall fire grille without connected ducts. This type of damper can be supplied equipped with a smoke detector.

Types of F-B90 damper actuation mechanisms

• H0

Basic damper design, manual activation mechanism with return spring and fusible thermal fuse set at 74°C.

• H2

Manual activation mechanism H0 + indication of open and closed position by 230V AC or 24V AC/DC limit switches.

• B230T or G230T

Activation mechanism with Belimo (B230T) or Gruner (G 230T) actuator with return spring, also equipped with thermoelectric actuation sensor with activation at 72°C. The actuator also includes limit switches with damper blade position indication. Power supply 230V AC.

• B24T or G24T

Actuation mechanism with Belimo (B24T) or Gruner (G24T) actuator with return spring, also equipped with thermoelectric actuation sensor with activation at 72°C. The actuator also includes limit switches with damper blade position indication. Power supply 24V AC/DC.

• BST0 or GST0

Activation mechanism with Belimo actuator (BST0, 24V AC/DC, power supply via 230V AC communication unit) or Gruner actuator (GST0, 24V AC/DC, power supply via 24V AC communication unit) with return spring, also equipped with thermoelectric actuation sensor with activation at 72°C. The actuator also includes limit switches with damper blade position indication. Power and communication units Belimo BKN 230-24 or Gruner fs-UFC230-2.

• B24T-SR or G24T-SR

Activation mechanism with Belimo (B24T-SR) or Gruner (G24T-SR) actuator with spring return and 0-10V control (possibility of setting the blade position in any position), also equipped with thermoelectric trigger sensor with activation at 72°C. The actuator also includes limit switches with signaling of the damper blade position. Power supply 24V AC/DC.

• BSD230T or GSD230T (only for dampers with grilles on both sides, i.e. type 11 and 22)

Activation mechanism equipped with a smoke detector with Belimo (BSD230T) or Gruner (GSD230T) actuator. The servo drives are powered by 24V AC/DC via a 230V AC powered communication unit. The servo drive is equipped with a return spring and thermoelectric actuation sensor with activation at 72°C. The actuator also includes limit switches with signaling of the damper blade position.Note: Actuators with smoke detector can only be supplied for dampers with grilles on both sides, i.e. types 11 or 22.

• BSD24T or GSD24T (only for dampers with grilles on both sides, i.e. type 11 and 22)

Activation mechanism equipped with a smoke detector with Belimo (BSD24T) or Gruner (GSD24T) actuator. The actuator power supply is 24V AC/DC. The actuator is equipped with a return spring, thermoelectric actuation sensor with activation at 72°C, the actuator also includes limit switches with signaling of the damper blade position.Note: Actuators with smoke detector can only be supplied for dampers with grilles on both sides, i.e. types 11 or 22.

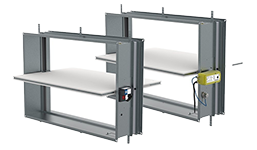

FDML

The FDML multi-blade fire dampers are HVAC elements serving as duct closures and can be used as fire wall closures in fire dividing structures. The FDML wall fire shutters prevent the spread of fire and fumes from one fire compartment to another. The fire shutter blades are controlled by an actuator. If the damper is hit by fire, it will close automatically by means of the actuator return spring.

The FDML can be used as a fire damper in air distribution systems as well as as a fire wall closure fitted with cover grilles in fire dividing structures. In the case of use as a fire damper, the dampers must be equipped with an access part for easy maintenance and inspection. The access part is to be installed directly behind the damper.

FDR

The FDR circular fire damper is designed to divide fire compartments and prevent the spread of toxic gases, smoke and flames. The FDR fire damper is an element of passive fire protection and, together with the method of its installation, is an inseparable part of the evaluation of the fire resistance of a building. The FDR circular fire damper is certified according to the ČSN EN 15 560 standard, tested according to ČSN EN 1366-2 and classified for EIS according to the 13501-3+A1 standard. The FDR fire dampers are made of galvanized sheet steel and contain lime-silica parts, fire-resistant carbon fiberglass, polyurethane foam and ethylene-propylene rubber.

Types of offered FDR fire dampers

FDR-3G

Damper with fire resistance up to 120 minutes, size range from 100 to 1000 mm, access door included.

FDR-3G-KS

Damper with fire resistance up to 120 minutes equipped with a square installation kit designed for a square installation opening, which is a fixed part of the damper. Size range from 100 to 630 mm.

FDR-3G-KR

Damper with fire resistance of up to 120 minutes equipped with a circular installation kit designed for a circular installation opening, which is a fixed part of the damper. Size range from 100 to 630 mm.

FDR-3G-OF

Damper with fire resistance up to 120 minutes equipped with a protection overflow grille on both sides. Size range from 200 to 630 mm.

The FDR fire dampers are supplied with manual control or with an actuator.

FDR fire damper with manual control

The FDR fire damper mechanism is activated when the temperature at the fuse reaches 74 °C (100 °C on request). In the event of a fire, the damper closes automatically within 10 seconds after the thermal fuse has blown. When the grille is closed, the grille blades remain locked in the closed position and can only be opened manually.

FDR fire damper with actuator

The FDR fire damper with actuator is equipped with limit switches as standard, optionally with power supply and communication unit. The actuator closes the damper based on a signal from the building management system (power failure) or when the thermoelectric temperature sensor temperature exceeds 72 °C (95 °C or 120 °C on request). The actuator supply circuit is interrupted and the spring closes the damper blades within 20 seconds.

Damper activation mechanism with manual control

• H0

Basic damper design, manual actuation mechanism with return spring and fusible thermal fuse with activation at 74 °C (100 °C on request). The mechanism is equipped with a protection cover IP 44

• H2

Manual activation mechanism H0 + indication of open and closed position by two limit switches for 230V AC or 24V AC/DC. The mechanism is equipped with a protective cover IP 44.

• H5-2

Manual activation mechanism H0 + activation mechanism with 24V AC/DC electromagnet in pulse connection (activation of damper blade closing occurs by impulse after voltage is applied to the electromagnet) + indication of closed and open position of the damper with two limit switches for 230V AC or 24V AC/DC. The mechanism is equipped with an IP 44 protection cover.

• H6-2

Manual activation mechanism H0 + activation mechanism with 230V AC electromagnet in pulse connection (activation of damper blade closing occurs by impulse after voltage is applied to the electromagnet) + indication of closed and open damper position by two limit switches for 230V AC or 24V AC/DC. The mechanism is equipped with an IP 44 protection cover.

Activation mechanism of the dampers controlled by an actuator

• B230T or G230T

Activation mechanism with Belimo (B230T) or Gruner actuator (G 230T) with return spring, further equipped with thermoelectric trigger sensor with activation at 72 °C. The actuator includes two limit switches for signaling the position of the damper blade. Power supply 230V AC.

• B24T or G24T

Activation mechanism with Belimo (B24T) or Gruner actuator (G24T) with return spring, further equipped with a thermoelectric trigger sensor with activation at 72 °C. The actuator includes two limit switches for signaling the position of the damper blade. Power supply 24V AC/DC.

• BST0 or GST0

Activation mechanism with Belimo actuator (BST0, 24V AC/DC, power supply via 230V AC communication unit) or Gruner actuator (GST0, 24V AC/DC, power supply via 24V AC communication unit) with return spring, further equipped with thermoelectric trigger sensor with activation at 72 °C. The actuator includes two limit switches for signaling the position of the damper blade. Power and communication units Belimo BKN 230-24 or Gruner fs-UFC230-2.

• B24T-W or G24T-W

Activation mechanism with Belimo (B24T-W) or Gruner actuator (G24T-W) with return spring, further equipped with thermoelectric trigger sensor with activation at 72 °C and cables for power supply and communication unit (communication unit is not part of the mechanism). The actuator includes two limit switches for signaling the position of the damper blade. Power supply 24V AC/DC.

• B24T-SR or G24T-SR

Activation mechanism with Belimo (B24T-SR) or Gruner actuator (G24T-SR) with return spring and 0-10V control (possibility to set the position of the blade in any position), further equipped with a thermoelectric trigger sensor with activation at 72 °C. The actuator also includes limit switches for signaling of the damper blade position. Power supply 24V AC/DC. This activation mechanism can only be used for dampers with DN ≥ 160 mm.

Catalog sheet of the product line: FDR-en.pdf. Declaration of performance of the product line: FDR_declaration-of-performance.pdf.

FKR-EU

The FKR-EU circular fire dampers for closing duct penetrations between fire compartments, for different installation methods, available in many sizes and designs. The FKR-EU fire dampers can be supplied in diameters 315 - 800 mm. Low pressure drop and acoustic performance levels with universal installation options. Integration into a central building management system using TROXNETCOM. Fire resistance class according to EN 13501-3, up to EI 120 (ve, ho, i ↔ o) S.

Optional equipment and accessories for the fire dampers FKR-EU: Electric actuator 24V / 230V. Starting temperature 72/95 °C or smoke detectors. Flanges. Cover grilles.

The FKR-EU fire damper complies with the European product standard EN 15650:2010 in circular design, with two access openings that can be opened without tools. Tested for fire performance according to EN 1366-2:2015 (300 Pa and 500 Pa underpressure), with CE marking.

Catalogue of the product series: FKR-EU-en.pdf. Declaration of performance of the product series: FKR-EU_declaration-of-performance.pdf. Instructions for use of the product series: FKR-EU-instructions-for-use.pdf

-

Two access openings

-

Available in explosion proof version (ATEX) for zones 1, 2, 21 and 22

-

Damper diameter from 315 mm

-

Optional installation of an additional actuator

-

Suitable for a wide range of installation situations (certified)

-

Hygienic certificate

FKRS-EU

FKRS-EU circular fire damper for closing duct transitions between fire compartiments, for various installation methods, available in many sizes and designs. The FKRS-EU fire dampers are available in diameters of 100 - 315 mm. Low pressure drop and sound power level with the possibility of universal installation. Integration into the central building management system using the TROXNETCOM. Fire resistance class according to EN 13501-3, up to EI 120 (ve, ho, i ↔ o) S.

Optional equipment and accessories for the FKRS-EU fire dampers: Electric actuator 24V / 230V. Starting temperature 72/95 °C or smoke detectors. Protection grilles.

The FKRS-EU fire damper is in accordance with the European product standard ČSN EN 15650 in circular design, with two access doors that can be opened without the use of tools. Tested in terms of fire protection properties according to ČSN EN 1366-2 (underpressure 300 Pa and 500 Pa), with CE marking.

Catalog sheet of the product line: FKRS-EU-data-sheet.pdf. Declaration of performance of the product line: FKRS-EU_declaration.pdf. Instructions for use of the product line: FKRS-EU-manual.pdf.

-

Explosion-proof design (ATEX) available for zones 1, 2, 21 and 22

-

Damper diameter from 100 mm

-

Possibility of additional installation of an actuator

-

For a wide range of installation situations (certified)

-

Hygienic certificate

FK2-EU

Four-sided fire damper for closing duct passages between fire compartments, for different installation types, available in many sizes and designs. The FK2-EU fire dampers are available in sizes: 200×100 - 1 500×800 mm, in 1 mm increments. Low pressure drop and sound power level with versatile installation options. Integration into the central building management system using TROXNETCOM. Fire resistance class up to EI 120 (ve, ho, i ↔ o) S. The FK2-EU fire dampers in the ATEX version can be available on request.

This damper replaces the previous types of fire dampers FKA-EU and FKS-EU. The new damper model brings many innovations over previous models.

FK2-EU fire damper options and accessories: Electric servo-drive 24V / 230V. Starting temperature 72/95 °C or smoke detectors.

The fire damper in accordance with European standard EN 15650 in square or four-sided design, with two large inspection openings that can be opened without tools. Tested for fire performance according to EN 1366-2 (suction 300 Pa and 500 Pa), with CE marking.

Product data sheet: FK2-EU.pdf. Product series declaration: FK2-EU-declaration-of-performance.pdf. Instruction manual for series: fk2-eu-manual.pdf. ATEX-certificate: ATEX-EU-declaration-Type-FK2-EU.pdf

- Made-to-measure dimensions for 1 mm

- Two inspection openings

- Damper height from 100 mm

- Possibility of retrofitting the servo-drive

- Reduction of pressure drop by 24% due to larger free cross section

- Suitable for a wide range of installation situations (certified)

- Hygienic certificate

FDMC

FDMC are fire dampers serving as closures in ducts of air handling equipment, which prevent the spread of fire and combustion products from one fire section to another by closing air ducts in the places of installation. The FDMC fire dampers are manufactured in diameters from 100 to 400mm.

-

tested to EN 1366-2 in conjunction with EN 1363-1

-

max. pressure difference at the damper 1 200 Pa

-

fire resistance according to EN 13501-3 + A1 EIS 60

-

for a maximum air velocity through the damper of 12 m/s

-

body made of galvanised sheet metal, damper blade made of lime-silica insulation board

FDMR

The FDMR fire dampers are HVAC devices that prevent the spread of fire and combustion products from one fire compartment to another. The FDMR fire damper blade automatically closes the air passage by means of a closing spring or a servo-drive. After closing the blade, the damper is sealed against the passage of smoke by a silicone seal. Upon customer request, silicone-free gaskets are available.

The FDMR fire dampers replace PKTM III, FDMD, PKTM 90 and PKTM90PM dampers.

- CE certification according to EN 15650

- tested according to EN 1366-2

- classified according to EN 13501-3+A1

- fire resistance: EIS 120-500 Pa, EIS 120, EIS 90, EIS 60

- tightness according to EN 1751, class C through the housing and class 3 through the damper blade

- C 10 000 cycling according to EN 15650

- corrosion resistance according to EN 15650

- EC Certificate of Conformity: 1391-CPR-2020/0004

- Declaration of performance PM/FDMR/01/19/1

- Hygiene assessment - Opinion No 1.6/pos/19/19b

FDMS / FDMS-VAV

The FDMS fire dampers are closures in the ducting of HVAC equipment, which prevent the spread of fire and combustion products from one fire compartment to another by closing the air duct in the places of installation. In the event of a fire, the FDMS fire damper blade automatically closes the ventilation duct by means of a closing spring or a return spring of the servo drive. The dampers are fitted with a collar, which replaces the function of the fire seal and thus simplifies its own installation in the fire compartment structure.

The FDMS-VAV fire dampers are additionally equipped with variable airflow control, as with VAV controllers. The FDMS-VAV dampers have the housing extended by an extension with a measuring cross and a controller. The FDMS-VAV damper is closed only by means of a servo drive.

Damper characteristics:

- CE certification according to EN 15650

- tested according to EN 1366-2

- classified according to EN 13501-3+A1

- fire resistance up to EIS 60

- tightness according to EN 1751, class C via body and class 2 via blade

- corrosion resistance according to EN 15650

- In the case of FDMS cycling test C 10 000 according to ČSN EN 15650

- In the case of FDMS-VAV cycling test C 20 000 according to ČSN EN 15650

- In the case of FDMS, the damper control is mechanical or by means of a servo drive

- In the case of FDMS-VAV, the dampers are only operated by means of a servo drive

- P-mark certification from the RISE institute in Sweden No. SC1433-17

Faultless operation of the dampers is ensured under the following conditions:

- Maximum air flow speed - 12 m/s.

- Maximum pressure difference on the damper - 2500 Pa.

- The operation of the dampers does not depend on the direction of air flow (circulation). In the case of the FDMS-VAV, the direction of air flow is precisely given.

- The damper can be placed in any position.

- The dampers are designed for air without abrasive, chemical and sticky additives.

- The dampers are designed for macroclimatic areas with a mild climate according to EN 60721-3-3.

- The temperature at the installation site is permitted in the range from -30 °C to +50 °C.

FDMA

The FDMA fire dampers are closures in HVAC systems that prevent the spread of fire and combustion products from one fire compartment to another. The damper blade automatically closes the air duct by means of a spring or a servo drive. The closing spring is actuated by releasing the trigger lever. The impulse to release the trigger lever can be manual, thermal or by means of an electromagnet. The return spring of the servo drive is activated when the BAT thermoelectric starter is activated. After closing the blade, the damper is sealed against the passage of smoke with a silicone seal. At the same time, the damper blade is embedded in a mass, which increases its volume due to the increasing temperature and closes the air duct airtight.

Characteristics of dampers:

- CE certification according to EN 15650

- tested according to EN 1366-2

- classified according to EN 13501-3+A1

- fire resistance EIS 120, EIS 90

- tightness according to EN 1751, class C through the damper body and class 2 through the damper blade

- cycling test in class C 10 000 according to EN 15650

- corrosion resistance according to EN 15650

- EC Certificate of Conformity No. 1391-CPR-2016/0158

- Declaration of performance No. PM/FDMA/01/20/1

- Hygienic assessment - Report No. 1.6/pos/19/19b

Operating conditions:

Faultless operation of the dampers is ensured under the following conditions:

a) maximum air flow speed of 12 m/s

maximum pressure difference of 1200 Pa

b) even distribution of the air flow in the entire cross-section of the damper.

The operation of the dampers does not depend on the direction of air flow. The dampers can be mounted in any position.

The dampers are designed for air mass without abrasive, chemical and adhesive additives.

Catalog sheet of the production line FDMA

Certificate of constancy of parameters FDMA

The FDMA fire dampers replace the PKTM 90 dampers.

FDMB

The FDMB fire dampers are closures in HVAC systems that prevent the spread of fire and combustion products from one fire compartment to another. The damper blade automatically closes the air duct by means of a spring or a servo drive. The closing spring is actuated by pressing the start button or by a pulse from the thermal fuse. The return spring of the servo drive is activated when the BAT thermoelectric starter is activated. After closing the blade, the damper is sealed against the passage of smoke with a silicone seal. At the same time, the damper blade is embedded in a mass, which increases its volume due to the increasing temperature and closes the air duct airtight.

Characteristics of dampers

- CE certification according to EN 15650

- Tested according to EN 1366-2

- Classified according to EN 13501-3+A1

- Fire resistance EIS 120, EIS 90

- Tightness according to EN 1751, class C through the damper body and class 2 through the damper blade

- Cycling test in class C 10 000 according to EN 15650

- Corrosion resistance according to EN 15650

- EC Certificate of Conformity No. 1391-CPR-0011/2014

- Declaration of performance No. PM/FDMB/01/20/1

- Hygienic assessment - Report No. 1.6/pos/19/19b

Operating conditions

Faultless operation of the dampers is ensured under the following conditions:

a) maximum air flow speed of 12 m/s

maximum pressure difference of 1200 Pa

b) even distribution of the air flow in the entire cross-section of the damper.

The operation of the dampers does not depend on the direction of air flow. The dampers can be mounted in any position.

The dampers are designed for air mass without abrasive, chemical and adhesive impurities.

Catalog sheet of the production line FDMB

Certificate of constancy of parameters FDMB

The FDMB fire dampers replace the PKTM-III dampers.

FDMQ

The FDMQ fire dampers are closures in HVAC systems that prevent the spread of fire and combustion products from one fire compartment to another. The damper blade automatically closes the air duct by means of a spring or a servo drive. The closing spring is actuated by pressing the start button or by a pulse from the thermal fuse. The return spring of the servo drive is activated when the BAT thermoelectric starter is activated. After closing the blade, the damper is sealed against the passage of smoke with a silicone seal. At the same time, the damper blade is embedded in a mass, which increases its volume due to the increasing temperature and closes the air duct airtight.

Characteristics of dampers

- CE certification according to EN 15650

- Tested according to EN 1366-2

- Classified according to EN 13501-3+A1

- Fire resistance EIS 120, EIS 90

- Tightness according to EN 1751, class C through the damper body and class 2 through the damper blade

- Cycling test in class C 10 000 according to EN 15650

- Corrosion resistance according to EN 15650

- EC Certificate of Conformity No. 1391-CPR-2020/0003

- Declaration of performance No. PM/FDMQ/01/20/1

- Hygienic assessment - Report No. 1.6/pos/19/19b

Operating conditions

Faultless operation of the dampers is ensured under the following conditions:

a) maximum air flow speed of 12 m/s, maximum pressure difference of 1200 Pa

b) even distribution of the air flow in the entire cross-section of the damper.

The operation of the dampers does not depend on the direction of air flow. The dampers can be mounted in any position.

The dampers are designed for air mass without abrasive, chemical and adhesive impurities.

Catalog sheet of the production line FDMQ

Certificate of constancy of performance FDMQ

The FDMQ fire dampers replace the PKTM 90-PM (four-sided dampers).

FDS

The FDS rectangular fire damper is designed to divide fire compartments and prevent the spread of toxic gases, smoke and flames. The FDS fire damper is an element of passive fire protection and, together with the method of its installation, is an inseparable part of the evaluation of the fire resistance of a building. The FDS rectangular fire damper is certified according to the ČSN EN 15 560 standard, tested according to ČSN EN 1366-2 and classified for EIS according to the 13501-3+A1 standard. The FDS fire dampers are made of galvanized sheet steel and contain lime-silica parts, fire-resistant carbon fiberglass, polyurethane foam and ethylene-propylene rubber.

Types of offered FDS fire dampers

FDS-3G

Damper with fire resistance up to 120 minutes, the casing is made of one piece. Size range from 100x100 to 1200x800 mm.

FDS-3G-KS

Damper with fire resistance up to 120 minutes equipped with a square installation kit designed for a square installation opening, which is a fixed part of the damper. Size range from 100 to 630 mm.

FDS-3G-OF

Damper with fire resistance up to 120 minutes equipped with protection overflow grille on both sides. Size range from 200x200 to 1200x800 mm.

FDS-EI90S

Damper with fire resistance up to 90 minutes, the casing is composed of two steel parts, conductively connected via a calcium-silicate central frame. Size range wider than 1200 mm and higher than 800 mm, maximum 1600x1000 mm.

FDS-EI120S

Damper with fire resistance up to 120 minutes, the casing consists of two steel parts, conductively connected via a calcium-silicate center frame. Size range wider than 1200 mm and higher than 800 mm, maximum 1600x1000 mm.

The FDS fire dampers are supplied with manual control or with an actuator.

FDS fire damper with manual control

The FDS fire damper mechanism is activated when the temperature at the fuse reaches 74 °C (100 °C on request). In the event of a fire, the damper closes automatically within 10 seconds after the thermal fuse has blown. When the grille is closed, the grille blades remain locked in the closed position and can only be opened manually.

FDS fire damper with actuator

The FDS fire damper with actuator is equipped with limit switches as standard, optionally with power supply and communication unit. The actuator closes the damper based on a signal from the building management system (power failure) or when the thermoelectric temperature sensor temperature exceeds 72 °C. The actuator supply circuit is interrupted and the spring closes the damper blades within 20 seconds.

Damper activation mechanism with manual control

• H0

Basic damper design, manual actuation mechanism with return spring and fusible thermal fuse with activation at 74 °C (100 °C on request). The mechanism is equipped with a protection cover IP 44

• H2

Manual activation mechanism H0 + indication of open and closed position by two limit switches for 230V AC or 24V AC/DC. The mechanism is equipped with a protective cover IP 44.

• H5-2

Manual activation mechanism H0 + activation mechanism with 24V AC/DC electromagnet in pulse connection (activation of damper blade closing occurs by impulse after voltage is applied to the electromagnet) + indication of closed and open position of the damper with two limit switches for 230V AC or 24V AC/DC. The mechanism is equipped with an IP 44 protection cover.

• H6-2

Manual activation mechanism H0 + activation mechanism with 230V AC electromagnet in pulse connection (activation of damper blade closing occurs by impulse after voltage is applied to the electromagnet) + indication of closed and open damper position by two limit switches for 230V AC or 24V AC/DC. The mechanism is equipped with an IP 44 protection cover.

Activation mechanism of the dampers controlled by an actuator

• B230T or G230T

Activation mechanism with Belimo (B230T) or Gruner actuator (G 230T) with return spring, further equipped with thermoelectric trigger sensor with activation at 72 °C. The actuator includes two limit switches for signaling the position of the damper blade. Power supply 230V AC.

• B24T or G24T

Activation mechanism with Belimo (B24T) or Gruner actuator (G24T) with return spring, further equipped with a thermoelectric trigger sensor with activation at 72 °C. The actuator includes two limit switches for signaling the position of the damper blade. Power supply 24V AC/DC.

• BST0 or GST0

Activation mechanism with Belimo actuator (BST0, 24V AC/DC, power supply via 230V AC communication unit) or Gruner actuator (GST0, 24V AC/DC, power supply via 24V AC communication unit) with return spring, further equipped with thermoelectric trigger sensor with activation at 72 °C. The actuator includes two limit switches for signaling the position of the damper blade. Power and communication units Belimo BKN 230-24 or Gruner fs-UFC230-2.

• B24T-W or G24T-W

Activation mechanism with Belimo (B24T-W) or Gruner actuator (G24T-W) with return spring, further equipped with thermoelectric trigger sensor with activation at 72 °C and cables for power supply and communication unit (communication unit is not part of the mechanism). The actuator includes two limit switches for signaling the position of the damper blade. Power supply 24V AC/DC.

• B24T-SR or G24T-SR

Activation mechanism with Belimo (B24T-SR) or Gruner actuator (G24T-SR) with return spring and 0-10V control (possibility to set the position of the blade in any position), further equipped with a thermoelectric trigger sensor with activation at 72 °C. The actuator also includes limit switches for signaling of the damper blade position. Power supply 24V AC/DC. This activation mechanism can only be used for dampers with a height H ≥ 160 mm. This version cannot be used for the FDS-EI90S / EI120S dampers.

Catalog sheet of the product line: FDS-en.pdf. Declaration of performance of the product line: FDS_declaration-of-performance.pdf.

FDR-Ex

The FDR-Ex circular fire damper is designed to divide fire compartments and prevent the spread of toxic gases, smoke and flames. The FDR-Ex fire damper is an element of passive fire protection and is, together with the method of its installation, an integral part of the assessment of the fire resistance of the building. The FDR-Ex circular fire damper is certified according to ČSN EN 15 560, tested according to ČSN EN 1366-2 and classified for EIS according to 13501-3+A1. The ATEX version is manufactured in accordance with Directive 2014/34/Eu for use in hazardous areas. The FDR-Ex fire dampers are made of galvanized steel sheet and contain lime-silica parts, fire-resistant carbon fiberglass, polyurethane foam and ethylene-propylene rubber.

The FDR-Ex fire dampers are available with manual or actuator operation, in a range of sizes from 100 to 1000 mm.

FDR-Ex fire dampers with manual operation

The actuation mechanism of the FDR-Ex fire damper is activated when the temperature at the fuse point reaches 74 °C (100 °C on request). In the event of a fire, the damper closes automatically within 10 seconds after the thermal fuse has melted. Once the damper is closed, the damper blades remain locked in the closed position and can only be opened manually.

FDR-Ex servo-drive actuated fire dampers

The FDR-Ex servo-drive actuated fire damper is equipped with limit switches as standard. The actuator closes the damper on a signal from the building management system (power interruption) or when the thermoelectric temperature sensor exceeds 72 °C. The actuator power circuit is interrupted and the spring closes the damper blades within 20 seconds.

- CE certified to EN 15 560

- Tested according to EN 1366-2

- Classification according to EN 13501-3+A1

- ATEX for gaseous and dusty environments

- II 2D Ex h IIIB T85°C...T100°C Db

- II 2G Ex h IIB T6...T5 Gb

- Manual activation mechanism with IP 44 protection

- Built-in inspection opening

Manual damper activation mechanism

-

H0-Ex - zone: 1.2 (Gb) 21.22 (Db)

Basic damper design, manual activation mechanism with return spring and thermal fuse with activation at 74° C (100° C on request). The mechanism is provided with an IP 44 protective cover. -

H2-Ex - zone: 1,2 (Gb, temperature limit T6) 21,22 (Db, temperature limit T85°C)

Manual activation mechanism H0 + indication of open and closed position by two limit switches at 230V AC or 24V AC/DC. The limit switches are in ATEX version. The mechanism is provided with an IP 44 protective cover.

Servo-drive damper activation mechanism

-

SET-EX - zone: 1,2 (Gb) 21,22 (Db)

Actuation mechanism with Schischek ExMax actuator with return spring, also equipped with thermoelectric actuation sensor with activation at 72°C. The actuator includes two limit switches to signal the position of the damper blade. Power supply 24...240 V AC/DC. -

SRT-EX - zone: only 2 (Gc); only 22 (Dc)

Actuation mechanism with Schischek RedMax actuator with return spring, also equipped with thermoelectric actuation sensor with activation at 72°C. The actuator includes two limit switches to signal the position of the damper blade. Power supply 24...240 V AC/DC.

Product Line Data Sheet: FDR-Ex-en.pdf

Product Line Declaration of Performance: FDR-Ex-declaration-of-performance.pdf

ATEX certificate: FDR-Ex-ATEX-certificate.pdf

FDS-Ex

The FDS-Ex square fire damper is designed to divide fire compartments and prevent the spread of toxic gases, smoke and flames. The FDS-Ex fire damper is an element of passive fire protection and is, together with the method of its installation, an integral part of the assessment of the fire resistance of the building. The FDS-Ex square fire damper is certified according to ČSN EN 15 560, tested according to ČSN EN 1366-2 and classified for EIS according to 13501-3+A1. The ATEX version is manufactured in accordance with Directive 2014/34/Eu for use in hazardous areas. The FDS-Ex fire dampers are made of galvanized steel sheet and contain lime-silica parts, fire-resistant carbon fiberglass, polyurethane foam and ethylene-propylene rubber.

The FDS-Ex fire dampers are available with manual operation or with actuator, in a range of sizes from 100x100 to 1600x1000 mm.

FDS-Ex fire dampers with manual operation

The actuation mechanism of the FDS-Ex fire damper is activated when the temperature at the fuse point reaches 74 °C (100 °C on request). In the event of a fire, the damper closes automatically within 10 seconds after the thermal fuse has melted. Once the damper is closed, the damper blades remain locked in the closed position and can only be opened manually.

FDS-Ex servo-drive actuated fire dampers

The FDS-Ex servo-drive actuated fire damper is equipped with limit switches as standard. The actuator closes the damper on a signal from the building management system (power interruption) or when the thermoelectric temperature sensor exceeds 72 °C. The actuator power circuit is interrupted and the spring closes the damper blades within 20 seconds.

- CE certified to EN 15 560

- Tested according to EN 1366-2

- Classification according to EN 13501-3+A1

- ATEX for gaseous and dusty environments

- II 2D Ex h IIIB T85°C...T100°C Db

- II 2G Ex h IIB T6...T5 Gb

- Manual activation mechanism with IP 44 protection

- Built-in inspection opening

Manual damper activation mechanism

-

H0-Ex - zone: 1.2 (Gb) 21.22 (Db)

Basic damper design, manual activation mechanism with return spring and thermal fuse with activation at 74° C (100° C on request). The mechanism is provided with an IP 44 protective cover. -

H2-Ex - zone: 1,2 (Gb, temperature limit T6) 21,22 (Db, temperature limit T85°C)

Manual activation mechanism H0 + indication of open and closed position by two limit switches at 230V AC or 24V AC/DC. The limit switches are in ATEX version. The mechanism is provided with an IP 44 protective cover.

Servo-drive damper activation mechanism

-

SET-EX - zone: 1,2 (Gb) 21,22 (Db)

Actuation mechanism with Schischek ExMax actuator with return spring, also equipped with thermoelectric actuation sensor with activation at 72°C. The actuator includes two limit switches to signal the position of the damper blade. Power supply 24...240 V AC/DC. -

SRT-EX - zone: only 2 (Gc); only 22 (Dc)

Actuation mechanism with Schischek RedMax actuator with return spring, also equipped with thermoelectric actuation sensor with activation at 72°C. The actuator includes two limit switches to signal the position of the damper blade. Power supply 24...240 V AC/DC.

Product Line Data Sheet: FDS-Ex-en.pdf

Product Line Declaration of Performance: FDS-Ex-declaration-of-performance.pdf

ATEX Certificate: FDS-Ex-ATEX-certificate.pdf